AccelStor storage solution helps an oil and gas field easily solve its data storage problem!

Challenges

As the foundation of the national economy, the petrochemical industry plays an essential role in boosting and promoting social development. Nowadays, digital transformation is necessary for long-term growth. The petroleum industry has also planned to accelerate its digitalization process as an essential strategy in response to unstable oil prices and energy transition.

At present, the oil and gas field is also undergoing digital transformation. Workflow automation and BI-related applications are the core of the current digital transformation. New challenges are brought to the underlying data storage from UAVs, Internet of Things, AI-related applications, graphic displays about real-time data, to the applications accurate to the second.

-

![2022122603175217]() Solution

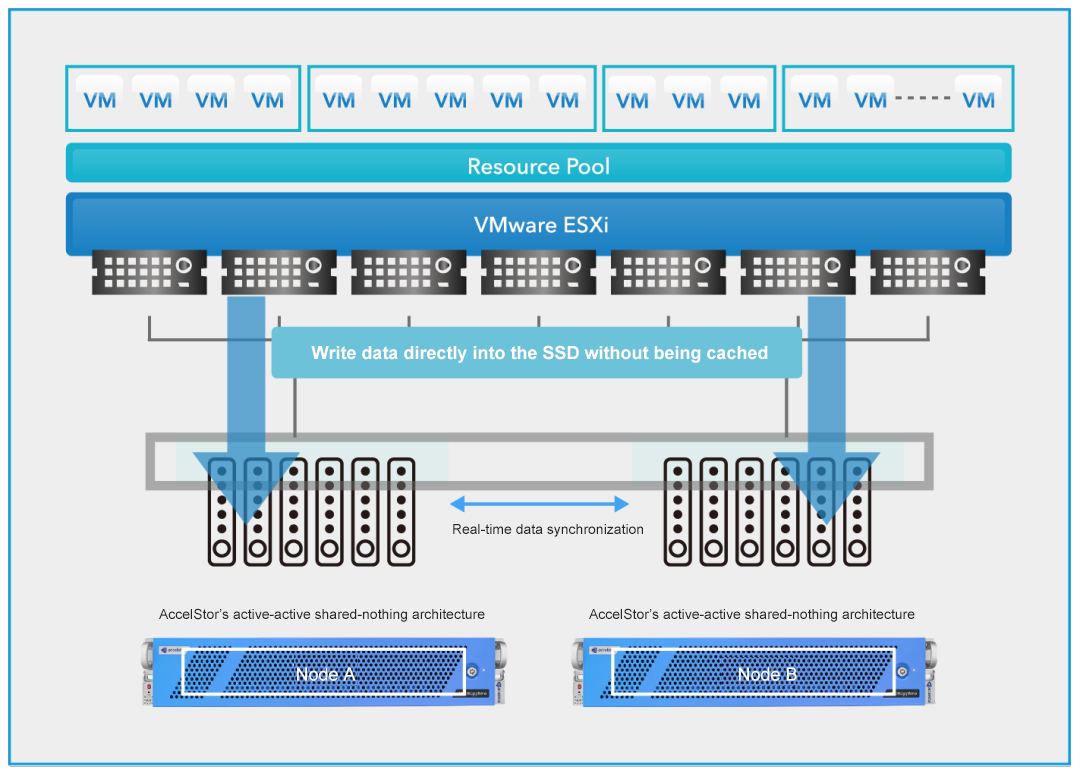

SolutionThe project charger of the oil and gas field storage architecture thinks safety and stability are essential when considering localization. After strenuous searching, they finally chose AccelStor's ultra-high availability models for its proprietary symmetric active-active shared-nothing storage architecture and patented FlexiRemap all-flash management technology.

-

Benefits

• 24x Efficiency Rise of Data Loading in Virtual Environment

Unlike conventional clone technology, AccelStor's innovative Free Clone technology only copies the system mapping table without consuming flash space, so the cloning time in virtualization is extremely short. As a result, it significantly improves the virtual machine's performance and decreases the backup recovery time. The new architecture design reduces the data loading time under the virtual environment from 6 hours to 15 minutes.• Avoid cache data loss due to unusual power failure.

Oilfields are usually located in the mountains, where the power supply is often unstable, which may lead to production data loss or even database service interruption. Such accidents may bring a severe influence on the petroleum industry. The data is written directly to the SSDs without being cached for acceleration, so there will be no risk of data loss when a power outage instantly.• Excellent Storage Technology with Reliable Operation and Maintenance Service

The remote location of oil and gas fields makes it more difficult to provide timely operation, maintenance, and failure recovery services. AccelStor's storage solutions took both technology and service into account. From the technical aspect, AccelStor's AFA uses the symmetric active-active shared-nothing architecture, which can ensure uninterrupted service even in the event of a large-scale failure of the entire storage pool. In addition, AccelStor provides customers with on-site parts replacement service. Even in the event of traffic interruption caused by extreme geological disasters, the system can be restored to a redundant state in time by replacing worn parts quickly to ensure uninterrupted system services.